iteanye le rona

ADDRESS:No. 89, Tsehang Road, Setereke sa Wuqiao, Toropo ea Zhuanghang, Setereke sa Fengxian

Tel:021-57407335

E-MAIL:[imeile e sirelelitsoe]

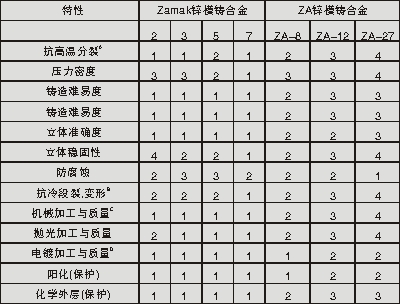

Basebeletsi ba lihlahisoa tsa zinc alloy ba tlameha ho tseba le ho utloisisa litšobotsi tsa lisebelisoa tsena, 'me tlhahlobo le tlhaloso ea litšobotsi tsa alloy ea zinc li sebelisoa hangata.

1. Overview of Zinc Alloy

Zinc alloy e thata ebile e matla, 'me ke sebaka se loketseng bakeng sa machining, ho bopa, khatiso,

tlhahiso le lisebelisoa tsa ho kopanya. Tafole e bonts'a thepa ea li-alloys tsa zinki.

Sehlahisoa se seng le se seng sa zinc alloy se na le litšobotsi tsa sona tse ikhethang, kahoo khetha sehlahisoa se molemo ka ho fetisisa

e lumellana le litlhoko tsa hau.

Litšobotsi tsa alloy ea zinc:

● thata ebile e tiile

● High conductivity

● Ho fetisa mocheso o phahameng

● Thepa e entsoeng ka theko e tlaase

●Maemo a mararo a nepahetseng le a tsitsitseng

● Ts'ebetso e ntle ea lebota le tšesaane

● Ts'ebetso e ntle ea ho pholisa, ho bonolo ho hokela

●Sehlahisoa se felileng sa boleng bo holimo

● Anti-corrosion e matla haholo

● E sebelisana hantle le tikoloho, e ka sebelisoa hape

Index ea litšupiso: 1=index e phahameng ka ho fetisisa, 5=index ea tlaase-tlaase

Ho hanyetsa ho arohana ha mocheso o phahameng.

Bokhoni ba motsoako oa ho hanyetsa khatello e hlahisoang ke liphetoho tsa mocheso, ho atolosoa ha mocheso

le ho honyela.

B e hanyetsana le ho robeha ha serame le deformation.

Bokhoni ba li-alloys ho hanela deformation, fracture, le ho kobeha maemong a mocheso o tlase.

C machining le boleng.

Tekolo e felletseng ea ho seha, thepa ea lebili, boleng ba sehlahisoa se felileng le bophelo ba lisebelisoa.

D ts'ebetso ea electroplating le boleng.

Bokhoni ba die castings ho amohela le ho boloka plating tlasa ts'ebetso e tloaelehileng.

2. Die-cast zinki alloy

Baqapi ba karolo ea meralo ba lokela ho ela hloko thepa ea li-alloys tsa zinki

e boletsoeng ka tlase. Li-alloys tsena li hanyetsana le mongobo le ho tsosoa ho feta aluminium

lits'epe tse kopantsoeng.

NO.1

No. 2 Alloy ea Zinc

Zinc Alloy No. 2 e boetse e tsejoa e le Kirksite. Ke motsoako o matla ka ho fetisisa oa lelapa lena. Leha ho le joalo,

ka lebaka la lintho tse ngata tsa koporo, e tla tsamaisana le litšobotsi tsa botsofali ka nako.

Phetoho ena e kenyelelitse keketseho e nyane ea molumo (0.0014 mm/[inin]) kamora lilemo tse 20, ka

katoloso e fokotsehileng le ho tlatsa polelo.

Le hoja alloy ea zinc No. 2 e le sesebelisoa se setle sa lisebelisoa, ha se hangata se sebelisoang ke bahlahisi ba shoang. E entse joalo

boits'oaro bo holimo ho feta li-alloys tse ling tsa zinki, 'me e boloka boima bo phahameng le matla ka mor'a moo

botsofali.

NO.2

No. 3 Alloy ea Zinc

Zinc alloy #3 ke thepa ea khetho ea zinki e shoang mme ke alloy e tsebahalang haholo ea zinki Leboea.

Amerika. Lintho tsa eona tse leka-lekaneng tsa 'mele le lik'hemik'hale ke tsona tse lakatsehang ka ho fetisisa, haholo-holo

e loketse liforomo tse bolaeang, tse nang le sebopeho se tsitsitseng sa mahlakore a mararo le anti-botsofali, e leng

hore na ke hobane'ng ha hlobo e ngata e e sebelisa joalo ka lihlahisoa tse tala. Zinc Alloy No. 3 e na le qetello e ntle ebile e loketse

ho penta, ho penta le lisebelisoa tsa chromic acid. Ke lisebelisoa tse tloaelehileng tsa ho lahla lefu.

Haeba ho hlokahala lisebelisoa tse phahameng tse thata, mefuta e meng ea li-alloys ea zinki e lokela ho nkoa.

NO.3

No. 5 Alloy ea Zinc

Zinc alloy No. 5 ke motsoako oa zinki o sebelisoang ka ho fetisisa Europe. Ka lebaka la koporo e phahameng

litaba, boima bo matla, 'me ka mor'a ho lahleheloa ke karolo ea ho otlolla (katoloso e tsoelang pele),

ho atolosoa ho bapisoa le motsoako oa zinki oa No. 3, 'me matla a eona a matlafatsoa. Sena

ho fokotseha ha elongation, ts'ebetsong ea bobeli, ho tla ama sebopeho sa tšepe, joalo ka

kobeha, mortise, swaging, crimping, tse lokelang ho nkoa ke moqapi. Hobane

karolo ea 'maraka ea No. 3 zinc alloy e phahame haholo, hangata baenjiniere ba likarolo ba sebelisa No. 3 ho e-na le hoo

ea No. 5 ha ho matlafatsa likarolo. Leha ho le joalo, haeba u etsa lihlahisoa tse hlokang ho feta

ts'ebetso ea elongation, re ntse re u khothalletsa hore u sebelise No. 5 zinc alloy. Leha ho le joalo

li-indices tsa li-alloys tsa zinc No. 3 le No. 5 li tšoana, motsoako oa zinc No. 5 o na le creep e matla haholoanyane

ho hanyetsa, 'me mefuta ka bobeli ea li-alloys e loketse bakeng sa machining arc. Ha mocheso

e nyoloha ho feta mocheso o tloaelehileng oa tikoloho, 'me ho na le litlhoko tse khethehileng tsa moralo bakeng sa

matla a ho jara a likarolo, motsoako oa zinc No. 5 ke khetho e ntle ka ho fetisisa.

NO.4

No. 7 Alloy ea Zinc

Zinc Alloy No. 7 e sebetsa e le phetoho ea Zinc Alloy No. 3 ho ntlafatsa die castability, ductility

le boleng ba bokahodimo. Boholo ba zinki motsoako No. 7 e sebediswa bakeng sa likarolo tšepe, 'me ha

ho thehoa ha hlobo ho na le litlhoko tse khethehileng bakeng sa ts'ebetso ea eona e latelang ea kopano, joalo

joalo ka crimping kapa qubung. Matla a shoe castability, empa hape a loketse ho hatella lerako le tšesaane.

Mefuta e meng e hloka matla a ho shoela, haholo-holo likarolo tse rarahaneng le tse teteaneng, empa sena

ha e bolele hore e hloka litlhoko tse khethehileng tse hatellang. E nepahetseng litekanyo tsa die le

li-parameter li bohlokoa ho qoba litlhase tse feteletseng nakong ea ho petsoha le tangent

tshebetso. Elongation ea boleng bo phahameng ba No. 7 zinc alloy e boetse e bonahala tlhahisong

ts'ebetso, empa e bonahala haholoanyane ts'ebetsong ea ho lokisa le ho sila ka lekhetlo la bobeli

Tshebetso.

NO.5

ZA-8 zinki motsoako

Liphesente tse ka bang tsa aluminium tsa index ea linomoro li bonts'a mofuta oa ZA

li-alloys li ruile haholo ka aluminium ho feta li-alloys tsa mofuta oa Zamak.

Zinc Alloy ZA-8 qalong e ne e etselitsoe li-alloys tsa ka ho sa feleng tse nang le boleng bo holimo

le litšoaneleho tsa plating. E sebelisoa ka ho khetheha e le thepa e khabisitsoeng. Le hoja motsoako ona ha o joalo

e ntle joaloka li-alloys tse ling bakeng sa ho lahla lefu, e na le thata ka ho fetisisa le ho hanyetsa

deformation. Mabapi le ts'ebetso ea lik'hemik'hale, ho thatafala, ho tiea le ho senyeha

khanyetso ea ZA-8 zinc alloy e matla ho feta li-alloys tse ling tsa zinki tse chesang. Ena ke eona

feela ZA alloy e ka sebelisoang bakeng sa hot chamber die casting.

NO.6

ZA-27 zinki motsoako

Ka lebaka la dikahare tse phahameng tsa aluminium tsa ZA-27 zinc alloy, e ka sebelisoa feela bakeng sa kamore e batang.

ho lahla. Li-alloys tsena li na le boima bo phahameng ka ho fetisisa le boima bo tlaase ka ho fetisisa lelapeng la ZA.

ZA-27 e fana ka khanyetso e matla ea moralo libakeng tse phahameng tsa mocheso ha li bapisoa

ho li-alloys tse ling tsa khoebo tsa zinki. E boetse e na le ho jara moroalo o phahameng le ho hanyetsa ho apara.

NO.7

Mofuta oa ACuZinc5 alloy ea zinki

ACuZinc5 mofuta oa zinki alloy e entsoe ke General Motors. Ka lebaka la koporo ea eona e eketsehileng

dikahare le ho fokotsa dikahare tsa aluminium, ho tiea ha eona le ho hanyetsa deformation li na le

e ntlafalitsoe haholo. Mofuta oa zinki oa mofuta oa ACuZinc5 o boetse o na le moroalo o motle

bokhoni.

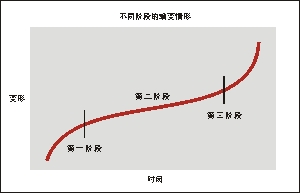

Zinc deformation (elongation tlas'a khatello e matla) e bolela deformation tlas'a ntho e itseng

nako le kgatello. Ka kakaretso ho na le mekhahlelo e meraro ea deformation:

Sehlopha sa 1 - Deformation ka likhatello tse nyenyane le tse fokolang butle-butle

Sehlopha sa 2 - Deformation e fokolang haholo empa e batla e phehella tlas'a khatello

Sehlopha sa 3 - Ho eketseha ha deformation tlas'a khatello ea kelello, hangata ho bakang ho robeha

The deformation level of zinc alloys ke boits'oaro bo ntseng bo tsoela pele ka nako.

Ka mohlala, karo-karolelano ea deformation-hula ha e tsoele pele, esita le ka tsitsipano e tlaase, 'me e itšoara hantle

ka tsela e fapaneng ka linako tse fapaneng, kahoo e baka phetoho ena e tsoelang pele ea lekhalo, kahoo li-alloys tsa zinki

ha ba na modulus e le 'ngoe ea elastic. palo. Matla a ho mamella (tension range) tlasa

mojaro o tsoelang pele o ipapisitse le mofuta o hlokahalang oa tsitsipano ea moralo (persente ea matla a katoloso).

Boleng ba ho sebetsa ba modulus ea elasticity le mefuta e mengata ea matla a thata e ka ba

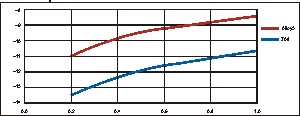

e fumanoeng ho tsoa ho li-graph tsa tlhahlobo ea deformation ea telescopic le deformation ea tšepe ea tšepe

teko ea No. 3 motsoako mocheso oa kamore. Hobane litekanyetso tsa deformation bakeng sa li-alloys No. 3 le

No. 5 e haufi, li-graph tsa bona li sebetsa ho li-alloys ka bobeli.

Mohlala: a. Haeba tsitsipano molemong oa tsitsipano ea moralo e le 0.2% mme bophelo bo hlokahalang ba ho sebetsa ke lilemo tse 5,

Tension range ke 15.1MPa. b. Matsatsi a 100 le tsitsipano ea 20.7MPa e hlahisa 0.1% deformation

Lintlha tsena li ka nkeloa sebaka ke liforomo tsa boenjiniere, empa ho lokela ho hlokomeloa hore ke tsona feela

e sebetsang ho li-bearings tse khethehileng libakeng tse khethehileng tsa mocheso. Mokokotlo oa hang-hang o emetse

deformation hang-hang tlas'a khatello e sebelisoang - ho khutlela sebopeho sa eona sa pele ha khatello e le

tlositsoe. Liphetoho tse ling tsohle tsa curve li kenyelletsa boleng bona hammoho le creep ho fella ka deformation e felletseng.

Joalo ka li-alloys tsohle, khatello ea khatello ha se eona feela ntho e sebetsang ho li-alloys tsa zinc, ts'ebetso

Thempereichara e ka boela ea etsa hore motsoako o kenelle. Deformation ea boemo ba pele e na le phello e fokolang ho alloy

No. 3, kahoo deformation ea boemo ba bobeli e ka sebelisoa ho hakanya katoloso kakaretso le

contraction ea alloy, ke hore, deformation ea boemo ba boraro tlas'a nako e telele le phahameng-khatello

tikoloho. The deformation, khatello, le likamano tsa mocheso tsa sehlopha sa bobeli sa li-alloys

No. 3 le No. 5 li bontšoa litšoantšong tsa tsona, ka ho latellana. Hoa lokela ho hlokomeloa hore sehlopha sa pele se hlaha

boits'oaro ba li-alloys tse ling le bona bo bohlokoa 'me ha boa lokela ho hlokomolohuoa.

Li-alloys tsa zinc li tlas'a botsofali, haholo-holo ka mocheso o phahameng. Liteko li bontšitse hore ka mor'a tse peli

lilemo, motsoako o tla fokotsa ho phahama ho hoholo ka 16% mocheso oa kamore, tlas'a khatello e phahameng,

kapa ho 75-95 ° C ka lilemo tse tharo. Ka hona, ntlha ea 0.8 e lokela ho eketsoa mofuteng oa matla a ho hula.

Balwa ka tsela e latelang.

U sebelisa lintlha tse tsoang ho Alloy No. 3, keketseho ea 10 ° C mocheso oa tšebeletso e ka sebelisoa ho

lekanya boleng ba deformation ea Alloy No. 5. Ka mohlala, e ka bang deformation tikoloho

ea alloy No. 5 ke 10°C e phahameng ho feta ea alloy No. 3.

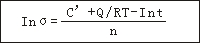

Foromo e latelang e ka bala ka nepo deformation ea No. 3 le ZA8 alloys zinki pakeng tsa

25°C le 120°C:

Ka mokhoa o ka holimo

σ=Matla a phahameng a mamellehang (Mpa)

T=Mocheso (K)

t = bophelo ba ho sebetsa (metsotsoana)

n=index ea khatello=3.5

Q=matla a tshebetso=106kJ/mol=106kJ/mol

R=khase e sa fetoheng=8.3143x10-3kJ/mol K

C' = kamehla e fumanoang tafoleng e ka tlaase

Ho fetola li-constants ka liforomo

Foromo e ka holimo e ka bala index e akaretsang ea khatello, mocheso, bophelo ba creep le index ea khatello ka har'a 50MPa bakeng sa boemo leha e le bofe ba ho qhoma ho tloha ho 0.2% ho isa ho 1%.

Tekanyo ea li-alloys tse ngata ha e tsitsa. Esita le lisampole tse peli tse bonahalang li tšoana li ka 'na tsa fapana ka lebaka la bophelo ba tsona bo fapaneng (katoloso ea mefuta), kahoo ebang ke lintlha tse fumanoeng tekong kapa foromo, lintlha tse ling kapa tse peli tse ling tsa sebele li bohlokoa. E lokela ho nkoa ho latela maemo a fapaneng.

EN

EN  ES

ES RU

RU PT

PT SV

SV DE

DE FR

FR