taura nesu

ADDRESS:No. 89, Yezhang Road, Wuqiao Nharaunda, Zhuanghang Town, Fengxian District

TEL:021-57407335

E-MAIL:[email inodzivirirwa]

Zinc alloy die-casting vashandi vanofanirwa kugona uye kunzwisisa hunhu hwezvinhu izvi, uye kuongororwa nekududzirwa kwezinc alloy maitiro anowanzoshandiswa.

1. Mhedziso yeZinc Alloy

Zinc alloy yakaoma uye yakasimba, uye inzvimbo yakanaka yekutsiva machining, kuumba, kudhinda,

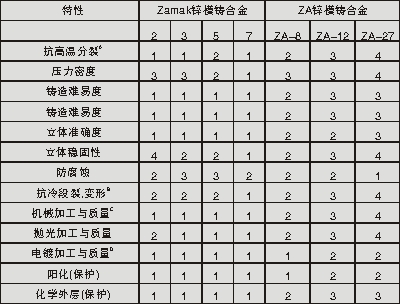

kugadzira uye kugadzira zvinhu. Tafura inoratidza zvinhu zve zinc alloys.

Imwe neimwe zinc alloy chigadzirwa ine yakasarudzika maitiro, saka sarudza chigadzirwa chakanyanya kunaka

inokodzera zvaunoda.

Zinc alloy maitiro:

●zvakaoma uye zvakasimba

● High conductivity

● High heat transfer

●Mbichi inodhura yakaderera

● Yakarurama uye yakagadzikana matatu-dimensionality

●Good thin-wall performance

● Kuita kwakanaka kwekutonhora, nyore kubatanidza

●Chigadzirwa chepamusoro chakapedzwa

● Super anti-corrosion

● Hushamwari hwezvakatipoteredza, hunogona kushandiswazve

Reference index: 1=indekisi yepamusoro, 5=indekisi yakaderera

Kupokana nekutsemuka kwekushisa kwepamusoro.

Iko kugona kweiyo alloy kuramba kumanikidzwa kunokonzerwa nekushanduka kwekushisa, kuwedzera kwemafuta

uye contraction.

B inopesana nechando kuputsika uye deformation.

Iko kugona kwema alloys kuramba deformation, kutsemuka, uye kukotama munzvimbo dzakaderera tembiricha.

C machining uye mhando.

Kuongorora kwakadzama kwekucheka, kucheka mavhiri zvivakwa, kupedzwa kwemhando yechigadzirwa uye hupenyu hwekushandisa.

D electroplating kugadzirisa uye kunaka.

Iko kugona kwekufa castings kugamuchira uye kuchengetedza plating pasi pekushanda kwakajairwa.

2. Die-cast zinc alloy

Chikamu chevagadziri vezvimiro vanofanirwa kufunga nezvezvinokambaira zvezinc alloys

yataurwa pazasi. Aya ma alloys anonyanya kushingirira kunyoro uye kuvhunduka kupfuura aluminium

alloys.

NO.1

Nhamba 2 Zinc Alloy

Zinc Alloy No. 2 inonziwo Kirksite. Ndiyo alloy yakasimba yemhuri iyi. Zvisinei,

nekuda kwehuwandu hwemhangura, huchaperekedzwa nehunhu hwekuchembera nekufamba kwenguva.

Shanduko iyi yaisanganisira kuwedzera kudiki kwevhoriyamu (0.0014 mm/[inin]) mushure memakore makumi maviri, ne

kuderedzwa kuwedzera uye kuzadza kutaura.

Kunyange zvazvo zinc alloy Nha. Zvakadaro

yakakwirira inokambaira maitiro kupfuura mamwe zinc alloys, uye inochengetedza kuoma kwakanyanya uye simba mushure

kuchembera.

NO.2

Nhamba 3 Zinc Alloy

Zinc alloy #3 ndicho chinhu chesarudzo che zinc inofa uye ndiyo inonyanya kufarirwa zinc alloy kuNorth.

America. Yayo yakaenzana yemuviri uye makemikari ehupfumi ndiyo inonyanya kudiwa, kunyanya

inokodzera kufa-kukanda molds, ine yakagadzikana-matatu-dimensional chimiro uye anti-kuchembera, inova

nei mold zhinji dzichiishandisa seyakabikwa. Zinc Alloy No. 3 ine kupera kwakanaka uye yakakodzera

plating, kupenda uye chromic acid application. Ivhareji yeavhareji inofa yekukanda zvinhu.

Kana yakakwirira kuomarara zvinhu zvinodiwa, mamwe marudzi e zinc alloys anofanirwa kutariswa.

NO.3

Nhamba 5 Zinc Alloy

Zinc alloy No. 5 ndiyo inonyanya kushandiswa zinc alloy muEurope. Nekuda kwemhangura yakakwirira

zviri mukati, kuoma kwakasimba, uye mushure mekurasikirwa nechikamu chekutambanudza (kuenderera mberi kwekuwedzera),

kuwedzera kunofananidzwa neNo. 3 zinc alloy, uye simba rayo rinowedzerwa. Izvi

kuderedzwa mukurebesa, muchiitiko chechipiri, kuchakanganisa chimiro chesimbi, senge

kukotama, kufa, kukwenya, kuputika, izvo zvinofanirwa kutariswa nemugadziri. Nokuti

chikamu chemusika cheNo. 3 zinc alloy yakakwirira kwazvo, zvikamu mainjiniya anowanzo shandisa Nha

yeNo. 5 pakusimbisa zvikamu. Nekudaro, kana iwe uri kugadzira zvigadzirwa zvinoda yakakwirira

elongation performance, isu tichiri kukurudzira kuti ushandise Nhamba 5 zinc alloy. Kunyangwe kupenga

indices ye zinc alloys Nhamba 3 uye Nhamba 5 yakafanana, zinc alloy Nhamba 5 ine simba rinokambaira.

kuramba, uye ese ari maviri marudzi ealoyi akakodzera kune arc machining. Kana tembiricha

inokwira kupfuura tembiricha yakajairika, uye pane zvakakosha dhizaini zvinodiwa zve

chimiro chekutakura kwezvikamu, iyo No. 5 zinc alloy inenge iri nani sarudzo.

NO.4

Nhamba 7 Zinc Alloy

Zinc Alloy No. 7 inoshanda sechigadziriso cheZinc Alloy No. 3 kuti ivandudze kufa castability, ductility

uye pamusoro pemhando. Yakawanda zinc alloy No. 7 inoshandiswa kune zvikamu zvesimbi, uye kana iyo

kuumbwa kwe mold kune zvakakosha zvinodiwa pakuita kwayo kunotevera magungano, akadaro

se crimping kana kuunganidza. Yakasimba kufa castability, asiwo yakakodzera kune yakaonda madziro kudzvanya.

Mamwe mold anoda akasimba kufa-castability, kunyanya yakaoma uye yakatetepa zvikamu, asi izvi

hazvirevi kuti zvinoda kudzvanya zvinodikanwa. Yakarurama die dimensions uye

ma paramita akakosha kuitira kuti udzivise sparks dzakawandisa panguva yekutsemuka uye tangent

process. Iyo yakakwirira-yepamusoro elongation yeNo. 7 zinc alloy inoratidzwawo mukugadzirwa

nzira, asi inonyanya kuratidzwa mukugadzirisa uye kugaya kushanda muchipiri

Process.

NO.5

ZA-8 zinc alloy

Iyo inenge iine aluminium yemukati muzana muzana yenhamba indekisi inoratidza kuti ZA-mhando

alloys akanyanya kupfuma mualuminium kupfuura Zamak-mhando alloys.

Zinc Alloy ZA-8 yakatanga kugadzirirwa zvechigarire die casting alloys ane yepamusoro mhando kupedzisa

uye plating unhu. Inonyanya kushandiswa sechinhu chekushongedza. Kunyangwe iyi alloy haisi

yakanaka semamwe alloys ekukanda kufa, ine yakanyanya kuoma uye kuramba

deformation. Panyaya yekushanda kwemakemikari, kuoma, kusimba uye deformation

kushorwa kweZA-8 zinc alloy yakasimba kupfuura mamwe anopisa-akanyungudutswa zinc alloys. Iyi ndiyo

chete ZA alloy inogona kushandiswa kupisa chamber die casting.

NO.6

ZA-27 zinc alloy

Nekuda kweiyo yakakwira aluminium yeZA-27 zinc alloy, inogona kushandiswa chete kukamuri inotonhora.

kufa kukandira. Aya alloys ane kuomarara kwepamusoro uye kuderera kwakanyanya mumhuri yeZA.

ZA-27 inopa yakasimba dhizaini kuramba munzvimbo dzakasimudzwa tembiricha zvichienzaniswa

kune mamwe mabhizimisi zinc alloys. Iyo inewo yakakwira kutakura-kutakura uye kupfeka kusagadzikana.

NO.7

ACuZinc5 mhando zinc alloy

ACuZinc5 mhando zinc alloy yakagadzirwa neGeneral Motors. Nekuda kwekuwedzerwa kwayo mhangura

zvemukati uye zvakaderedzwa aluminium zvemukati, kusimba kwayo uye kuramba deformation vane

yakavandudzwa zvakanyanya. Iyo ACuZinc5 mhando zinc alloy zvakare ine yakanaka inotakura

simba.

Zinc deformation (elongation under heavy pressure) zvinoreva deformation pasi pechimwe

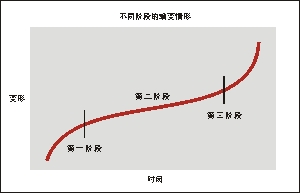

nguva nekumanikidzwa. Pane kazhinji nhanho nhatu dze deformation:

Kirasi 1 - Deformation padiki uye zvishoma nezvishoma kudzikira kudzvinyirira

Kirasi 2 - Yakanyanya kusimba asi yakada kuenderera deformation pasi pekumanikidzwa

Giredhi 3 - Kuwedzera kwe deformation pasi pekushushikana, kazhinji kunokonzeresa kuputsika

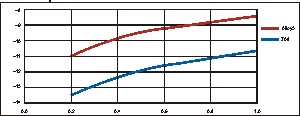

Iyo deformation level ye zinc alloys hunhu hunokura curvilinearly nenguva.

Semuenzaniso, iyo deformation-kudhonza reshiyo haisi kuenderera, kunyangwe pakadzika tension, uye kuzvibata

zvakasiyana panguva dzakasiyana dzenguva, nekudaro zvichikonzera ichi chinoenderera curve shanduko, saka zinc alloys

hauna kana imwe elastic modulus. nhamba. The withstand force (tension range) pasi

kuenderera mberi mutoro kunobva pane inodiwa dhizaini tension range (extension force percentage).

Iko kukosha kwekushanda kweiyo modulus ye elasticity uye huwandu hwesimba resimba rinogona kuva

yakawanikwa kubva kumagirafu eiyo telescopic deformation bvunzo uye simbi plate deformation

bvunzo yeNo. 3 alloy pane tembiricha yekamuri. Nokuti deformation zvinokosha kuti alloys No. 3 uye

Nhamba 5 iri pedyo, magirafu avo anoshanda kune zvose alloys.

Muenzaniso: a. Kana kushushikana kuri mudhizaini yekunetsana kuri 0.2% uye hupenyu hwekushanda hunodiwa makore mashanu,

tension range i15.1MPa. b. 100 mazuva uye 20.7MPa tension inoburitsa 0.1% deformation

Aya data anogona kutsiviwa muinjiniya mafomula, asi zvinofanirwa kucherechedzwa kuti iwo chete

inoshanda kune akakosha mabhengi munzvimbo dzakakosha tembiricha. Iyo pakarepo curve inomiririra

iyo yekukurumidza deformation pasi pekumanikidzwa kwakaiswa - kudzokera kune chimiro chayo chepakutanga kana kudzvanywa kuri

kubviswa. Dzimwe shanduko dzese dzemacurve dzinosanganisira kukosha uku pamwe nekukwira kunokonzera deformation yakazara.

Sezvineiwo ese maalloys, iyo yekumanikidza siyana haisi iyo chete chinhu chinoshanda pane zinc alloys, iyo inoshanda

tembiricha inogonawo kuita kuti alloy ifambe. Iyo deformation yedanho rekutanga haina mhedzisiro pane alloy

No. 3, saka deformation yechipiri nhanho inogona kushandiswa kufungidzira yose kuwedzera uye

chibvumirano che alloy, ndiko kuti, deformation yezinga rechitatu pasi penguva refu uye yakakwirira-kudzvinyirira

nharaunda. Iyo deformation, kudzvanywa, uye tembiricha hukama hwechipiri giredhi yealloys

Nhamba 3 uye Nhamba 5 inoratidzwa mumifananidzo yavo, maererano. Zvinofanira kucherechedzwa kuti giredhi rokutanga zvinokambaira

maitiro emamwe alloys akakoshawo uye haafanire kuregeredzwa.

Zinc alloys ari pasi pekuchembera, kunyanya kune tembiricha yakakwira. Miedzo yakaratidza kuti mushure memaviri

makore, iyo alloy inoderedza kukwira kwekufamba ne16% patembiricha yekamuri, pasi pekumanikidzwa kukuru,

kana pa75-95°C kwemakore matatu. Nokudaro, chikamu che 0.8 chinofanira kuwedzerwa kune simba rekudhonza.

Yakaverengwa sezvinotevera.

Uchishandisa data kubva kuAlloy No. 3, kuwedzera kwe10 ° C pakupisa kwebasa kunogona kushandiswa

fungidzira kukosha kwekugadzirisa kweAlloy No. 5. Semuenzaniso, iyo inenge yakasvibiswa mamiriro ezvinhu

yealloy Nhamba 5 ndeye 10 ° C yakakwirira kupfuura iyo yealloy Nha.

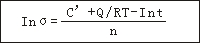

Iyo inotevera formula inogona kunyatsoverenga deformation yeNo. 3 uye ZA8 zinc alloys pakati

25°C uye 120°C:

Mune formula iri pamusoro

σ=Simba repamusoro rinoshivirika (Mpa)

T=Tembiricha (K)

t = hupenyu hwekushanda (masekondi)

n=pressure index=3.5

Q=simba rekuita =106kJ/mol=106kJ/mol

R=gasi nguva dzose=8.3143x10-3kJ/mol K

C' = nguva dzose inowanikwa kubva patafura iri pasi apa

Kushandura maconstants kuita formulas

Iyo iri pamusoro fomula inogona kuverenga iyo yakazara yekumanikidza index, tembiricha, hupenyu hwekukambaira uye kudzvinyirira index mukati me50MPa kune chero mamiriro ezvinokambaira muhuwandu hwe0.2% kusvika 1%.

Iyo dhigirii yekukambaira kweakawanda alloys haina kugadzikana. Kunyangwe masampuli maviri anoita seakafanana anogona kunge akasiyana nekuda kwehupenyu hwawo hwekukwira (yekuwedzera huwandu), saka ingave iyo data yakawanikwa muyedzo kana fomula, chimwe kana zviviri zvekuwedzera zvinhu zvakakosha zvakare. Inofanira kuverengwa maererano nemamiriro ezvinhu akasiyana.

EN

EN  ES

ES RU

RU PT

PT SV

SV DE

DE FR

FR