hu rau peb

CHAW NYOB:No. 89, Yezhang Txoj Kev, Wuqiao Zej Zog, Nroog Zhuanghang, Fengxian Ib Cheeb Tsam

TEL:021-57407335

E-XA:[email tiv thaiv]

Zinc alloy tuag-casting cov neeg ua haujlwm yuav tsum paub thiab nkag siab cov yam ntxwv ntawm cov ntaub ntawv no, thiab kev tshuaj xyuas thiab kev txhais cov yam ntxwv ntawm zinc alloy feem ntau yog siv.

1. Txheej txheem cej luam ntawm Zinc Alloy

Zinc alloy yog ib qho nyuaj thiab muaj zog, thiab nws yog ib qho zoo tagnrho hloov rau machining, molding, printing,

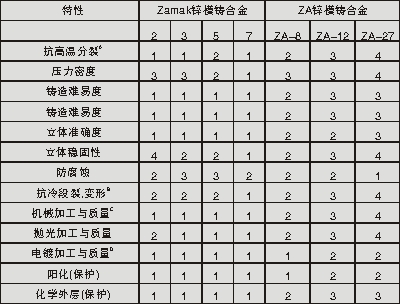

manufacturing thiab assembling cov ntaub ntawv. Lub rooj qhia cov khoom ntawm zinc alloys.

Txhua cov khoom siv zinc alloy muaj nws cov yam ntxwv tshwj xeeb, yog li xaiv cov khoom zoo tshaj plaws

phim koj cov kev xav tau.

Cov yam ntxwv ntawm zinc alloy:

● nyuaj thiab ruaj khov

● High conductivity

●High kub hloov

● Cov khoom siv raug nqi qis

● Precise thiab ruaj khov peb-dimensionality

● Kev ua tau zoo ntawm phab ntsa nyias

● Kev ua haujlwm txias txias, yooj yim rau kev sib txuas

● Cov khoom tiav tiav

● Super tiv thaiv corrosion

● Ib puag ncig tus phooj ywg, recyclable

Reference index: 1 = siab tshaj index, 5 = lowest index

Ib qho kev tiv thaiv kub kub sib cais.

Lub peev xwm ntawm cov alloy los tiv thaiv lub siab tsim los ntawm kev hloov kub, thermal expansion

thiab contraction.

B yog resistant rau txias tawg thiab deformation.

Lub peev xwm ntawm cov alloys tiv thaiv deformation, tawg, thiab dabtsi yog khoov nyob rau hauv qis kub ib puag ncig.

C machining thiab zoo.

Kev ntsuam xyuas tag nrho ntawm kev txiav, txiav log zog, tiav cov khoom zoo thiab lub neej cuab yeej.

D electroplating ua thiab zoo.

Lub peev xwm ntawm tuag castings txais thiab tswj plating nyob rau hauv ib txwm ua haujlwm.

2. Tuag-cam khwb cia zinc alloy

Cov neeg tsim qauv tsim ib feem yuav tsum coj mus rau hauv tus account cov khoom nkag ntawm zinc alloys

hais hauv qab no. Cov alloys no tiv taus cov dej noo thiab poob siab dua li txhuas

cov hlau

NO.1

No. 2 Zinc Alloy

Zinc Alloy No. 2 tseem hu ua Kirksite. Nws yog lub zog tshaj alloy ntawm tsev neeg no. Txawm li cas los xij,

vim muaj cov ntsiab lus tooj liab siab, nws yuav nrog rau cov yam ntxwv ntawm kev laus lub sijhawm.

Qhov kev hloov pauv no suav nrog qhov nce me ntsis hauv ntim (0.0014 mm / [inin]) tom qab 20 xyoo, nrog rau

txo extensibility thiab sau articulation.

Txawm hais tias zinc alloy No. 2 yog cov khoom siv zoo, nws tsis tshua siv los ntawm cov neeg tsim khoom tuag. Nws muaj

siab dua tus cwj pwm dua li lwm cov zinc alloys, thiab nws khaws cov hardness siab thiab lub zog tom qab

laus.

NO.2

No. 3 Zinc Alloy

Zinc alloy #3 yog cov khoom xaiv rau zinc tuag thiab yog zinc alloy nrov tshaj plaws nyob rau sab qaum teb

Asmeskas. Nws cov khoom sib npaug ntawm lub cev thiab tshuaj lom neeg yog qhov xav tau tshaj plaws, tshwj xeeb tshaj yog

haum rau tuag-casting pwm, nrog ruaj khov peb-dimensional zoo thiab anti-aging, uas yog

vim li cas feem ntau cov pwm siv nws ua raw khoom. Zinc Alloy No. 3 muaj qhov ua tiav zoo thiab tsim nyog rau

plating, painting thiab chromic acid siv. Nws yog tus qauv nruab nrab tuag casting khoom.

Yog tias xav tau cov ntaub ntawv hardness siab dua, lwm hom zinc alloys yuav tsum xav txog.

NO.3

No. 5 Zinc Alloy

Zinc alloy No. 5 yog cov zinc alloy feem ntau siv nyob hauv Europe. Vim yog tooj liab siab dua

cov ntsiab lus, lub hardness yog muaj zog, thiab tom qab poob ib feem ntawm stretch (nruam txuas ntxiv),

lub extensibility yog piv nrog rau No. 3 zinc alloy, thiab nws lub zog yog txhim khu kev qha. Qhov no

txo qhov elongation, nyob rau hauv cov txheej txheem thib ob, yuav cuam tshuam rau cov duab ntawm cov hlau, xws li

khoov, mortise, swaging, crimping, uas yuav tsum tau txiav txim siab los ntawm tus tsim qauv. Vim

kev lag luam feem ntawm No. 3 zinc alloy yog siab heev, cov engineers feem ntau siv No. 3 hloov

ntawm No. 5 thaum ntxiv dag zog rau qhov chaw. Txawm li cas los xij, yog tias koj tab tom ua cov khoom uas xav tau ntau dua

elongation kev ua tau zoo, peb tseem xav kom koj siv No. 5 zinc alloy. Txawm tias lub creep

Indices ntawm zinc alloys No.3 thiab No.5 zoo ib yam, zinc alloy No.5 muaj zog creep

tsis kam, thiab ob hom alloys yog haum rau arc machining. Thaum kub

nce siab tshaj qhov qub ambient kub, thiab muaj tshwj xeeb tsim yuav tsum tau rau

cov qauv bearing muaj peev xwm ntawm qhov chaw, No. 5 zinc alloy yog qhov kev xaiv zoo dua.

NO.4

No. 7 Zinc Alloy

Zinc Alloy No.7 ua raws li kev hloov kho ntawm Zinc Alloy No.3 los txhim kho kev tuag castability, ductility

thiab nto zoo. Feem ntau zinc alloy No. 7 yog siv rau cov khoom siv hlau, thiab thaum lub

kev tsim cov pwm muaj cov kev cai tshwj xeeb rau nws cov kev ua haujlwm tom qab sib dhos, xws li

raws li crimping los yog piling. Muaj zog tuag castability, tab sis kuj haum rau nyias phab ntsa nias.

Qee cov pwm yuav tsum muaj zog tuag-castability, tshwj xeeb tshaj yog qhov nyuaj thiab muag heev, tab sis qhov no

tsis txhais hais tias nws yuav tsum tau tshwj xeeb nias. Qhov tseeb tuag qhov ntev thiab

parameters yog qhov tseem ceeb nyob rau hauv thiaj li yuav zam dhau lub txim thaum lub sij hawm sib cais thiab tangent

txheej txheem. Qhov zoo elongation ntawm No. 7 zinc alloy kuj yog qhov tshwm sim hauv kev tsim khoom

txheej txheem, tab sis nws yog ntau dua reflected nyob rau hauv kev kho thiab sib tsoo ua hauj lwm nyob rau hauv lub thib ob

txheej txheem.

NO.5

ZA-8 zinc alloy

Qhov kwv yees ntawm cov ntsiab lus txhuas feem pua ntawm cov lej ntsuas qhia tau tias ZA-hom

alloys yog cov nplua nuj nyob hauv txhuas ntau dua li Zamak-hom alloys.

Zinc Alloy ZA-8 yog Ameslikas tsim rau kev tuag casting alloys nrog kev ua tiav zoo

thiab plating zoo. Nws yog tshwj xeeb yog siv los ua cov khoom siv kho kom zoo nkauj. Txawm hais tias qhov no alloy tsis yog

zoo li lwm yam alloys rau tuag casting, nws muaj qhov zoo tshaj plaws hardness thiab kuj rau

deformation. Nyob rau hauv cov nqe lus ntawm tshuaj lom neeg kev ua tau zoo, hardness, firmness thiab deformation

tsis kam ntawm ZA-8 zinc alloy muaj zog dua lwm cov kub-smelted zinc alloys. Qhov no yog qhov

tsuas yog ZA alloy uas tuaj yeem siv rau kub chamber tuag casting.

NO.6

ZA-27 zinc alloy

Vim yog cov ntsiab lus ntawm cov aluminium siab ntawm ZA-27 zinc alloy, nws tsuas yog siv tau rau chav txias

tuag casting. Cov alloys no muaj qhov hardness siab tshaj plaws thiab qis tshaj plaws nyob rau hauv ZA tsev neeg.

ZA-27 muaj cov qauv tsim muaj zog tshaj plaws nyob rau hauv qhov kub thiab txias ib puag ncig piv

rau lwm yam kev lag luam zinc alloys. Nws kuj muaj siab load-nqa thiab hnav tsis kam.

NO.7

ACuZinc5 hom zinc alloy

ACuZinc5 hom zinc alloy yog tsim los ntawm General Motors. Vim nws nce tooj liab

cov ntsiab lus thiab txo cov ntsiab lus ntawm aluminium, nws cov firmness thiab tsis kam mus deformation muaj

tau zoo heev. Lub ACuZinc5 hom zinc alloy kuj muaj cov kabmob zoo

muaj peev xwm.

Zinc deformation (elongation nyob rau hauv hnyav hnyav) yog hais txog deformation nyob rau hauv ib tug tej yam

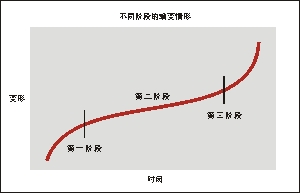

sij hawm thiab siab. Feem ntau muaj peb theem ntawm deformation:

Chav Kawm 1 - Deformation ntawm me me thiab nce qib qis dua

Chav Kawm 2 - Tsis muaj zog tshaj tab sis yuav luag tas li deformation nyob rau hauv siab

Qib 3 - Kev nce ntawm deformation nyob rau hauv kev ntxhov siab, feem ntau ua rau tawg

Qib deformation ntawm zinc alloys yog tus cwj pwm uas tsim curvilinearly nrog lub sijhawm.

Piv txwv li, qhov deformation-rub piv tsis tas li, txawm tias tsis tshua muaj zog, thiab coj tus cwj pwm

sib txawv ntawm lub sijhawm sib txawv, yog li ua rau qhov kev hloov pauv txuas ntxiv no, yog li zinc alloys

tsis muaj ib qho elastic modulus. tus lej. The withstand force (tension range) nyob rau hauv

nruam load yog raws li qhov yuav tsum tau tsim nro ntau yam (extension force feem pua).

Kev ua hauj lwm tus nqi ntawm cov modulus ntawm elasticity thiab ntau yam ntawm lub tensile quab yuam yuav ua tau

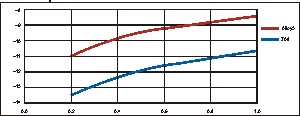

tau los ntawm cov duab kos ntawm telescopic deformation test thiab hlau phaj deformation

kuaj ntawm No. 3 alloy ntawm chav tsev kub. Vim tias qhov deformation qhov tseem ceeb rau alloys No. 3 thiab

No. 5 nyob ze, lawv cov duab siv rau ob qho tib si alloys.

Piv txwv li: a. Yog tias qhov nro ntawm qhov kev tsim nro yog 0.2% thiab lub neej ua haujlwm yuav tsum yog 5 xyoos,

qhov nro ntau yog 15.1MPa. b. 100 hnub thiab 20.7MPa nro ua 0.1% deformation

Cov ntaub ntawv no tuaj yeem hloov pauv rau hauv cov qauv engineering, tab sis nws yuav tsum raug sau tseg tias lawv tsuas yog

muaj feem xyuam rau tshwj xeeb bearings nyob rau hauv tshwj xeeb kub ib puag ncig. Lub instantaneous nkhaus sawv cev

qhov tam sim ntawd deformation nyob rau hauv lub siab thov - rov qab mus rau nws qub zoo thaum lub siab yog

tshem tawm. Tag nrho lwm cov kev hloov nkhaus suav nrog tus nqi no ntxiv rau kev nkag mus ua rau tag nrho deformation.

Raws li nrog tag nrho cov alloys, lub siab ntau yam tsis yog tib yam uas ua rau zinc alloys, kev khiav hauj lwm

kub kuj tuaj yeem ua rau cov hlau nkag mus. Lub deformation ntawm thawj theem tsis tshua muaj kev cuam tshuam rau alloy

Tsis yog 3, yog li qhov deformation ntawm qib thib ob tuaj yeem siv los kwv yees qhov kev nthuav dav tag nrho thiab

contraction ntawm alloy, uas yog, deformation ntawm qib peb nyob rau hauv lub sij hawm ntev thiab high-pressure

ib puag ncig. Lub deformation, siab, thiab kub kev sib raug zoo ntawm qib ob ntawm alloys

No.3 thiab No.5 yog qhia nyob rau hauv lawv daim duab, raws li. Nws yuav tsum tau muab sau tseg tias thawj qib creep

kev coj cwj pwm ntawm lwm cov alloys kuj tseem ceeb thiab yuav tsum tsis txhob muab pov tseg.

Zinc alloys raug rau kev laus, tshwj xeeb tshaj yog thaum kub siab. Kev ntsuam xyuas tau pom tias tom qab ob

xyoo, cov hlau yuav txo cov creep elongation los ntawm 16% ntawm chav tsev kub, nyob rau hauv siab siab,

los yog ntawm 75-95 ° C rau peb xyoos. Yog li ntawd, ib qho tseem ceeb ntawm 0.8 yuav tsum tau ntxiv rau lub zog rub tawm.

Muab xam raws li nram no.

Siv cov ntaub ntawv los ntawm Alloy No. 3, qhov nce ntawm 10 ° C ntawm qhov kev pabcuam kub tuaj yeem siv rau

kwv yees tus nqi deformation ntawm Alloy No. 5. Piv txwv li, kwv yees deformation ib puag ncig

ntawm alloy No. 5 yog 10 ° C siab dua li ntawm alloy No. 3.

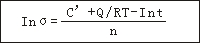

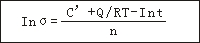

Cov mis hauv qab no tuaj yeem xam qhov deformation ntawm No.3 thiab ZA8 zinc alloys ntawm

25 ° C thiab 120 ° C:

Hauv cov qauv saum toj no

σ= siab tshaj lub zog (Mpa)

T = Kub (K)

t = ua hauj lwm lub neej (seconds)

n=siab index=3.5

Q = kev ua zog = 106kJ / mol = 106kJ / mol

R = gas tas li = 8.3143x10-3kJ/mol K

C' = tas mus li tau los ntawm cov lus hauv qab no

Hloov qhov tsis tu ncua rau hauv cov qauv

Cov qauv saum toj no tuaj yeem xam qhov ntsuas qhov ntsuas siab, qhov kub thiab txias, lub neej nkag thiab siab Performance index nyob rau hauv 50MPa rau tej yam creep mob nyob rau hauv ntau ntawm 0.2% mus rau 1%.

Qhov degree ntawm creep ntawm feem ntau alloys tsis ruaj khov. Txawm hais tias ob qho piv txwv zoo ib yam tuaj yeem sib txawv vim lawv lub neej nkag mus (kev nthuav dav), yog li txawm tias nws yog cov ntaub ntawv tau txais hauv qhov kev sim lossis cov qauv, ib lossis ob qhov tseem ceeb ntxiv kuj tseem ceeb. Nws yuav tsum raug coj mus rau hauv tus account raws li cov xwm txheej sib txawv.

EN

EN  ES

ES RU

RU PT

PT SV

SV DE

DE FR

FR