contact us

ADDRESS:No. 89, Yezhang Road, Wuqiao Community, Zhuanghang Town, Fengxian District

TEL:021-57407335

E-MAIL:[email protected]

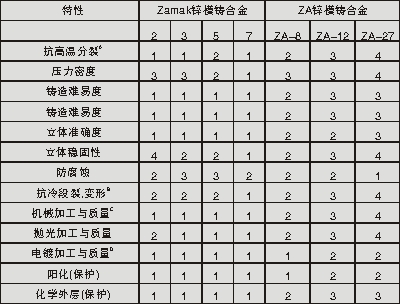

Zinc alloy die-casting personnel must master and understand the characteristics of these materials, and the analysis and interpretation of zinc alloy characteristics are commonly used

1. Overview of Zinc Alloy

Zinc alloy is hard and strong, and it is an ideal substitute for machining, molding, printing,

manufacturing and assembly materials. The table shows the properties of zinc alloys.

Each zinc alloy product has its unique characteristics, so choose the product that best

suits your needs.

Zinc alloy characteristics:

●hard and firm

●High conductivity

●High heat transfer

●Low cost raw material

●Precise and stable three-dimensionality

●Good thin-wall performance

●Good cooling performance, easy to connect

●High quality finished product

●Super anti-corrosion

●Environmentally friendly, recyclable

Reference index: 1=highest index, 5=lowest index

A resistance to high temperature splitting.

The ability of the alloy to resist the pressure generated by temperature changes, thermal expansion

and contraction.

B is resistant to cold fracture and deformation.

The ability of alloys to resist deformation, fracture, and bending in low temperature environments.

C machining and quality.

Comprehensive evaluation of cutting, cutting wheel properties, finished product quality and tool life.

D electroplating processing and quality.

The ability of die castings to accept and maintain plating under normal operation.

2. Die-cast zinc alloy

Part structural designers should take into account the creep properties of zinc alloys

mentioned below. These alloys are more resistant to moisture and shock than aluminum

alloys.

NO.1

No. 2 Zinc Alloy

Zinc Alloy No. 2 is also known as Kirksite. It is the strongest alloy of this family. However,

due to the high copper content, it will be accompanied by aging characteristics over time.

This change included a slight increase in volume (0.0014 mm/[inin]) after 20 years, with

reduced extensibility and fill articulation.

Although zinc alloy No. 2 is a good tool material, it is rarely used by die producers. It has

higher creep behavior than other zinc alloys, and it retains high hardness and strength after

aging.

NO.2

No. 3 Zinc Alloy

Zinc alloy #3 is the material of choice for zinc dies and is the most popular zinc alloy in North

America. Its balanced physical and chemical properties are the most desirable, especially

suitable for die-casting molds, with stable three-dimensional shape and anti-aging, which is

why most molds use it as raw material. Zinc Alloy No. 3 has a good finish and is suitable for

plating, painting and chromic acid applications. It is a standard average die casting material.

If higher hardness materials are required, other types of zinc alloys should be considered.

NO.3

No. 5 Zinc Alloy

Zinc alloy No. 5 is the most commonly used zinc alloy in Europe. Due to the higher copper

content, the hardness is stronger, and after losing part of the stretch (continuous extension),

the extensibility is compared with the No. 3 zinc alloy, and its strength is enhanced. This

reduction in elongation, in the second process, will affect the shape of the metal, such as

bending, mortise, swaging, crimping, which should be considered by the designer. Because

the market share of No. 3 zinc alloy is very high, parts engineers usually use No. 3 instead

of No. 5 when strengthening parts. However, if you are making products that require higher

elongation performance, we still recommend you to use No. 5 zinc alloy. Although the creep

indices of zinc alloys No. 3 and No. 5 are similar, zinc alloy No. 5 does have stronger creep

resistance, and both types of alloys are suitable for arc machining. When the temperature

rises beyond the normal ambient temperature, and there are special design requirements for

the structural bearing capacity of the parts, the No. 5 zinc alloy is relatively a better choice.

NO.4

No. 7 Zinc Alloy

Zinc Alloy No. 7 acts as a modification of Zinc Alloy No. 3 to improve die castability, ductility

and surface quality. Most zinc alloy No. 7 is used for metal components, and when the

forming of the mold has special requirements for its subsequent assembly operations, such

as crimping or piling. Stronger die castability, but also suitable for thin wall pressing.

Some molds require stronger die-castability, especially complex and delicate parts, but this

does not mean that it requires special pressing requirements. Accurate die dimensions and

parameters are essential in order to avoid excessive sparks during the splitting and tangent

process. The high-quality elongation of No. 7 zinc alloy is also reflected in the production

process, but it is more reflected in the correction and grinding operation in the second

process.

NO.5

ZA-8 zinc alloy

The approximate aluminum content percentage of the numerical index shows that the ZA-type

alloys are significantly richer in aluminum than the Zamak-type alloys.

Zinc Alloy ZA-8 was originally made for permanent die casting alloys with high quality finish

and plating qualities. It is especially used as a decorative material. Although this alloy is not

as good as other alloys for die casting, it has the best hardness and resistance to

deformation. In terms of chemical performance, the hardness, firmness and deformation

resistance of ZA-8 zinc alloy are stronger than other hot-smelted zinc alloys. This is the

only ZA alloy that can be used for hot chamber die casting.

NO.6

ZA-27 zinc alloy

Due to the high aluminum content of ZA-27 zinc alloy, it can only be used for cold chamber

die casting. These alloys have the highest hardness and the lowest density in the ZA family.

ZA-27 offers the strongest design resistance in elevated temperature environments compared

to other commercial zinc alloys. It also has high load-carrying and wear resistance.

NO.7

ACuZinc5 type zinc alloy

ACuZinc5 type zinc alloy was developed by General Motors. Due to its increased copper

content and reduced aluminum content, its firmness and resistance to deformation have

been significantly improved. The ACuZinc5 type zinc alloy also has a good load-bearing

capacity.

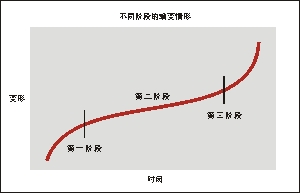

Zinc deformation (elongation under heavy pressure) refers to deformation under a certain

time and pressure. There are generally three levels of deformation:

Class 1 - Deformation at small and progressively lower pressures

Class 2 - Weakest but almost persistent deformation under pressure

Grade 3 - Escalation of deformation under stress, usually resulting in fracture

The deformation level of zinc alloys is a behavior that develops curvilinearly with time.

For example, the deformation-pull ratio is not continuous, even at low tension, and behaves

differently at different time periods, thus causing this continuous curve change, so zinc alloys

do not have a single elastic modulus. number. The withstand force (tension range) under

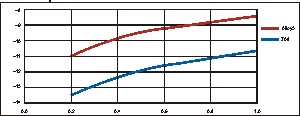

continuous load is based on the required design tension range (extension force percentage).

The working value of the modulus of elasticity and the range of the tensile force can be

obtained from the graphs of the telescopic deformation test and the metal plate deformation

test of No. 3 alloy at room temperature. Because the deformation values for alloys No. 3 and

No. 5 are close, their graphs apply to both alloys.

Example: a. If the tension in the design tension range is 0.2% and the required working life is 5 years,

the tension range is 15.1MPa. b. 100 days and 20.7MPa tension produces 0.1% deformation

These data can be substituted into engineering formulas, but it should be noted that they are only

applicable to special bearings in special temperature environments. The instantaneous curve represents

the immediate deformation under applied pressure - returning to its original shape when the pressure is

removed. All other curve changes include this value plus creep to result in total deformation.

As with all alloys, the pressure range is not the only thing that acts on zinc alloys, the operating

temperature can also cause the alloy to creep. The deformation of the first level has little effect on alloy

No. 3, so the deformation of the second level can be used to estimate the overall expansion and

contraction of the alloy, that is, the deformation of the third level under long-term and high-pressure

environments. The deformation, pressure, and temperature relationships of the second grade of alloys

No. 3 and No. 5 are shown in their diagrams, respectively. It should be noted that the first grade creep

behavior of other alloys is also important and should not be neglected.

Zinc alloys are subject to aging, especially at elevated temperatures. Tests have shown that after two

years, the alloy will reduce the creep elongation by 16% at room temperature, under high pressure,

or at 75-95°C for three years. Therefore, a factor of 0.8 should be added to the pulling force range.

Calculated as follows.

Using the data from Alloy No. 3, an increase of 10°C at the service temperature can be used to

estimate the deformation value of Alloy No. 5. For example, the approximate deformation environment

of alloy No. 5 is 10°C higher than that of alloy No. 3.

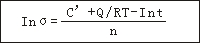

The following formula can accurately calculate the deformation of No. 3 and ZA8 zinc alloys between

25°C and 120°C:

In the above formula

σ=Maximum tolerable force (Mpa)

T=Temperature (K)

t = working life (seconds)

n=pressure index=3.5

Q=activity energy=106kJ/mol=106kJ/mol

R=gas constant=8.3143x10-3kJ/mol K

C' = constant obtained from the table below

Substituting constants into formulas

The above formula can calculate the comprehensive pressure index, temperature, creep life and pressure index within 50MPa for any creep condition in the range of 0.2% to 1%.

The degree of creep of most alloys is unstable. Even two seemingly identical samples may be different due to their respective creep life (expansion range), so whether it is the data obtained in the test or the formula, one or two additional actual factors are also important. It should be taken into account according to different situations.

EN

EN  ES

ES RU

RU PT

PT SV

SV DE

DE FR

FR